The Jute Story: from yarn to rope

PART 5/5

The final stage is the

production of rope from yarns, and I discovered many factors that cause

production issues, and now understand better how to avoid them.

Following the ordeal of driving from Dhaka to the jute growing area, and to the yarn mill, the internal flight was remarkably uneventful, almost relaxing. It was a false dawn. Chittagong traffic made Dhaka look positively organised. To make matters worse, the main thoroughfares through the city are often just mud mixed with red brick dust. Monsoon rains create vast puddle lakes, under which potholes large enough to swallow rickshaws lurk unseen. The poverty all around was incredible and very humbling.

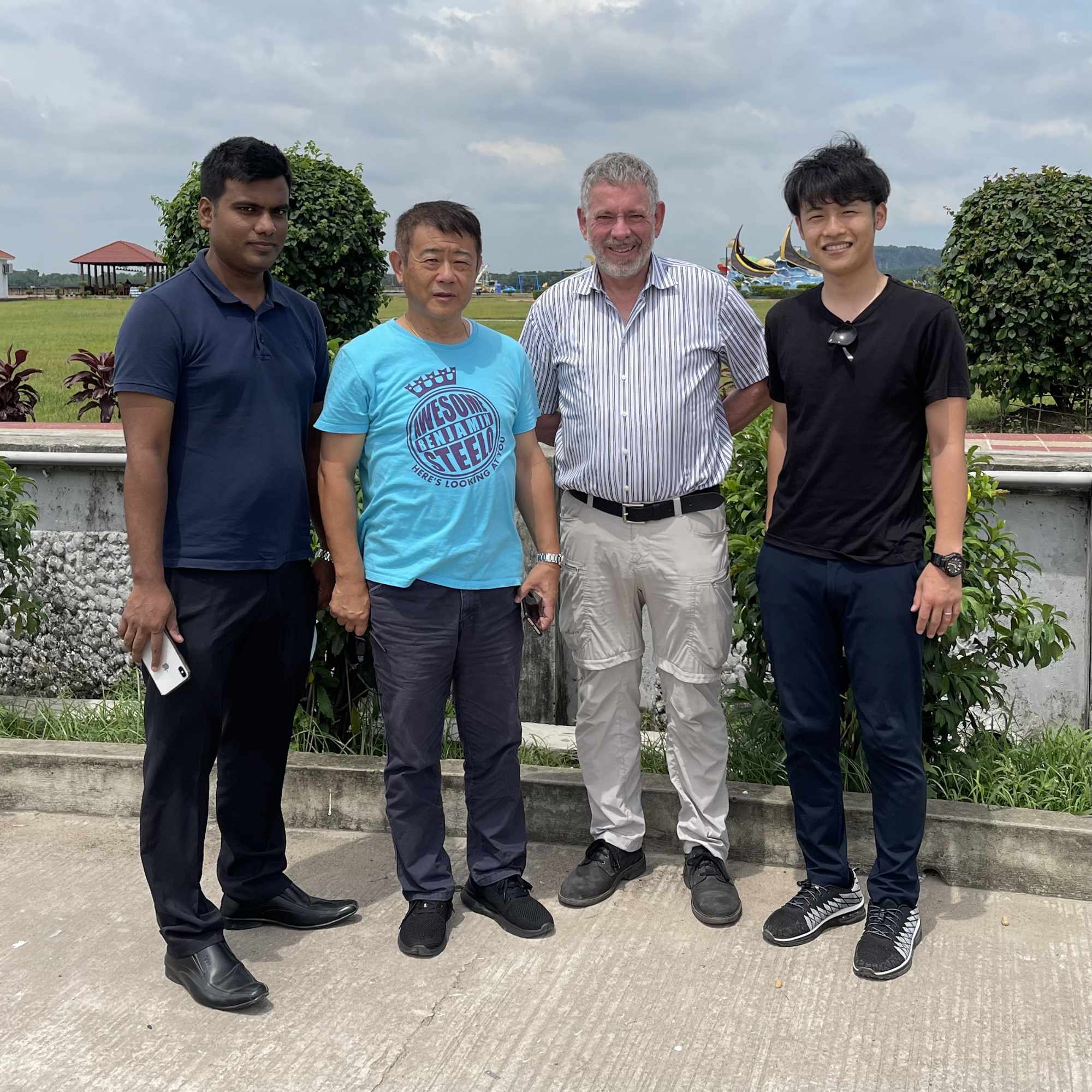

Kiyonori san, Yu san, Ifte and I were collected by the company driver, proficient in driving through the utter madness. I was deposited at my modern western hotel, noting the signed cricket bats on the reception walls. They kindly waited while I checked in, went to my room, and refreshed under the shower. Through my window I looked down on the Zohur Ahmed Chowdhury Stadium. All visiting international test cricket teams stay there.

When ready, I re–joined my hosts waiting patiently in the lobby, we drove to what they considered a top restaurant. No alcohol was on offer in this very conservative Muslim city. Knowing the score, Kiyonori san had smuggled in a fresh bottle of Johnny Walker in his bag acquired duty free somewhere on his journey from Narita via Bangkok. We ordered Pepsi, and surreptitiously charged our glasses under the table, topping up with the cola to hide our misdemeanour. I go along willingly. This is how bonds in business are truly made.

The curry was delicious, not so spicy, and loaded with plenty of lime juice. The palate cleansing and cooling yoghurt afterwards, served in individual ceramic pots probably the best I have ever tasted, slightly sweet. Then the manager came and discussed a problem in Bengali with Ifte. The local family on the next table had figured out our transgression with the whiskey. We had to pay up and leave rapidly like naughty schoolboys before the police arrived.

The next morning, I was collected early and we headed to the rope manufacturing offices on one of their production sites. Things were going to get rather bizarre.

As we arrived, the entire office staff were on the steps to the entrance waiting to greet me. As we got out of the car, it wasn’t Bengali or English as they all called out, “Ohayo Gozaimasu!” in unison. Fortunately, in the previous week I’d spent the long drives to and from Antwerp, and then on the flights brushing up by Japanese language skills. We got into the air–conditioned boardroom, and the on–site President, Koji san, Kiyonori san’s younger brother who has lived here nearly 2 decades introduced me to his Bengali office staff, all in Japanese.

Then it was my turn to explain the history and goals of AMATSUNAWA, what the product is going to be used for, and my analysis of the global market I’ve been following for more than a decade. Apart from the Japanese, they’re all Muslim. I gritted my teeth and awaited the shock. But there was none. More inquisitiveness on how to tie. The sado–erotic nature of the application was accepted without the bat of an eyelid. A lightweight volunteer, the Quality Control Manager was invited, and I tied my Takatekote design with a single 16m line. There was joviality as each management employee tested lifting him by hand from the Battendome lashing, as he confirmed it was surprisingly comfortable.

Everything became fine detail. I showed them the tiny section of a sacred piece of rope we aim to better. 7m of it was gifted to me in a club in Ginza, Tokyo a very long time ago. I was told it was one of Akechi Denki’s, but have no way to corroborate, apart from the direct link from the individual who gave it to me. Over the years, sections have been sent to Kolkata University, The National Jute Laboratory of Bangladesh, various yarn mills and ropemakers. All informed me it couldn’t be jute, because it’s so perfect. A very expensive analysis by a forensic botanist at The Natural History Museum, London confirmed it was, and a long wild goose chase was finally ended.

The team marvelled at the quality as we reverse engineered it together. The Procurement Manager stated almost immediately what season and where it was grown. I’m astounded. Yes, he said, we can do this, but several factors have to change, or be modified. Having cut out all the unscrupulous middle agents raises the chances. I brought in my photonics expertise so we can install machine vision to improve lay ratio tolerance, and to eliminate imbalances and loops, and we agreed to copy the mill’s special yarn knotting to replace the bulky reef knots.

We headed out to production, which, if you closed your eyes, you’d have believed we were in Japan. Every Bengali worker greeted us with a loud ‘Konnichiwa!’. In this factory, Japanese is the second language after Bengali. Ifte, the Bangladeshi General Manager lived in Japan for 6 years, working at headquarters. He’s fluent.

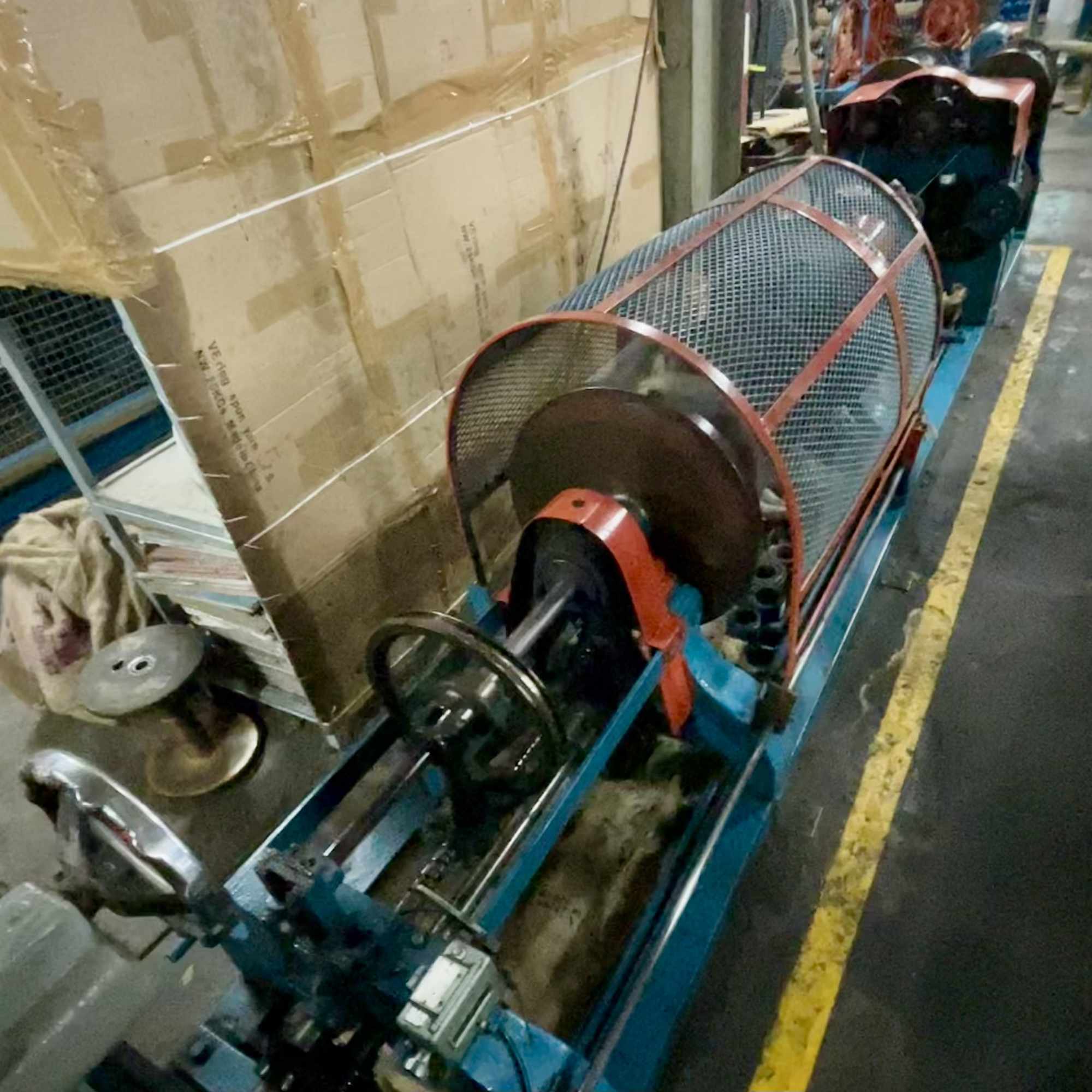

As we got to the strander machine, I was asked not to photograph a section of their carefully guarded technology. All their machinery on this product line has been designed and built to order in Japan. Jute is one of the most challenging materials to wind due to its finesse. High–speed machine gearings habitually rip the yarns, and what we would consider ‘loose lay’ is far more susceptible to imbalances and loops.

Our terminology loose, medium and tight–lay don’t exist at rope manufacturing. Only tpi – twist rotations per inch. What we consider loose is easier to produce with white petroleum (JBO) batched rougher yarn because it withstands the mechanical processes better. Kiyonori san explained the way to achieve our goals is to use the best quality 100% raw Tosha, multiple VOT batched with the best soybean oil on the market, 4–stage carded, 4–stage drawn, and double coated. This will produce a slightly tighter lay, but retain the softness we require for Shibari due to increased pliancy. It should be another massive improvement.

The other critical factor is in the vegan jojoba oil and Mokurō wax quality, mix, blending, delivery and dosing we created at AMATSUNAWA, and the management of the application system. After first production, we realised how the best Tosha fibre will suck in the mix, and so it needed to be tripled to avoid conditioned Jouyoku product drying out.

Our afternoon visitors were from the sea freight forwarding agent. I watched Ifte’s eyes flash, understanding he has a rock–solid intuition for bullshit and deceit. In this part of the world, in this business, there are so many interlopers out for a large slice for doing very little. Life is a risky business. Jute bondage rope supply fraught with hurdles most users may never appreciate. A market supplied in tonnage on a non–returnable basis.

With all the business complete, they wanted to take me souvenir shopping. But I’m a rotten tourist, and age has caught up with me. Like a locomotive out of steam I opted for a couple of hours sleep in my hotel. It was very hard traveling, and harder work. The education was invaluable, but the high humidity takes its toll.

In the evening the driver collected me and

we negotiate the absurd city traffic again. We arrived in a secluded area, and

I was shown into a private Chinese house, and taken upstairs to join my hosts

for dim sum in a private room. As I sat, I saw the screen and the microphone. I

braced myself, and tried to remember the words to Kyu Sakamoto’s classic ‘Ue o

Muite Arukō’. It could be a jaw–dropper, but had to come from memory, because

the little Kanji I can read will flash quickly up on the screen.

As we ate, Kiyonori san asked if I know Dan Oniroku. ‘Hana to Hebi?’ I answered. He grinned. His son Yu san, just coming up 30 and Ifte have no idea what we were laughing about together. We spent the rest of the meal explaining what pink film and theatre is to the younger, innocent generation, and how lack of knowledge, misunderstanding and misrepresentation had spread through Gaijin on what they consider Japanese. Next time, I told them, I’ll take you to see a friend in Takasaki–shi who has an SM bar. I’ll tie to show you.

While the schedule was punishing, the education was immense – in both directions, and puts us now on the final path to perfect the optimum product for application, and turn AMATSUNAWA into a global brand. This was concreted when Kiyonori san offered their support to go after supplying the Japanese high street general rope vendors and Shibari market.

©AMATSUNAWA GmbH 2022